Mounting environmental concerns have sparked growing interest in the development of renewable energy resources, with biofuels leading the way among industries likely to provide substitutes for fossil fuels.

Biofuels are liquid or gaseous fuels produced through the conversion of biomass. Biomass, the biodegradable fraction of organic matter, is considered a source of renewable energy. Contrary to fossil energy, therefore, biofuels contribute to energy self-reliance by reducing greenhouse gas emissions (GHG). They are used in a variety of industries, including in manufacturing and in the transportation sector, notably in hybrid vehicles. In general, biofuels are divided into three generations, based on the origin of the biomass and the processes used to convert it :

- First-generation biofuels are developed using plant biomas produced directly from food-based resources (i.e., beets, corn, sugar cane, wheat, etc.). First-generation biofuels accounts for most of the mature biofuels currently available on the market. In addition to presenting a mixed environmental balance sheet, they are criticized for acting as a source of competition to the food chain and for their use of lands. In order to address this problem and deliver improved energy performance, researchers are working to develop advanced biofuels, that’s to say second- and third-generation biofuels.

- Second-generation biofuels are produced from non-edible residues, whether or not they are food-based. These residuals include lignocellulosic biomass (i.e., wood, plant stalks, straw, organic waste, etc.) made up of molecules such as cellulose and lignin, both of which are rich in renewable carbon.

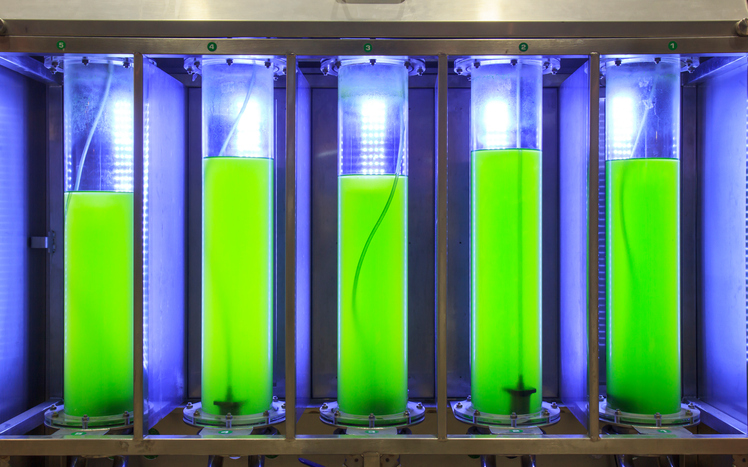

- Third-generation biofuels produced using microorganisms, such as microalga, are currently under development. These microorganisms can be cultivated in photobioreactors, which make it possible to control physicochemical parameters, or in outdoor basins. What’s more, algal biomass is thought to offer better performance and production than plant biomass. In fact, it presents an elevated photosynthesis rate – i.e., the rate of conversion of solar energy into chemical energy – to go along with higher CO2 Its potential remains relatively untapped, however.

While second- and third-generation biofuels have yet to reach full maturity, they are said to offer better energy efficiency than first-generation biofuels, with the added advantage that they don’t conflict with the food chain, which is why they tend to be favoured by researchers. Third-generation biofuels include bioethanol, biodiesel, biobutanol or biomethane.

It’s important to mention that the development of these biofuels is made possible by biorefining technologies with the capacity to produce several by-products and process various raw materials. Biorefinery facilities optimize the value extracted from biomass for purposes of developing bioproducts. For example, these facilities may include photobioreactors used in the conversion of algal biomass. These units can use several processes to convert biomass, including gasification and methanization. Gasification is the process whereby carbon from biomass, carbon dioxide and water vapour is converted into a combustible gas called syngas, with the process taking place entirely inside a reactor. Methanization, for its part, involves the use of bacteria, in the absence of oxygen, to decompose organic matter for purposes of producing biogas with the use of a digester.

This article presents the innovative technologies developed in Montréal to produce biofuels in response to current environmental concerns, and it highlights the city’s technological potential in this emerging field.

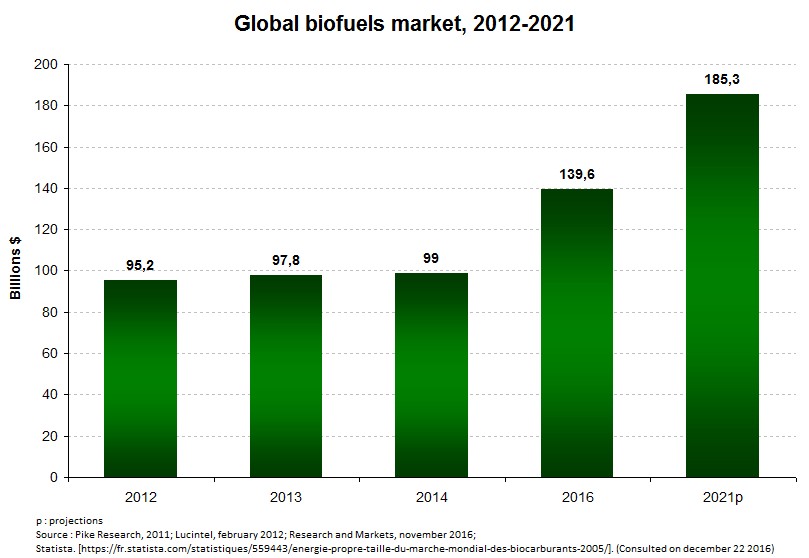

GROWTH OF THE GLOBAL MARKET FOR BIOFUELS

The global market for biofuels was estimated to be in the order of $140 billion in 2016, compared to $95 billion in 2012. This is equivalent to an average annual growth rate of 10% over four years. According to recent estimates by the firm Pike Research, this market should record average annual growth of about 6% over the next five years, to reach $185 billion in 2021.

The still-emerging market for second-generation biofuels, meanwhile, is expected to reach $24 billion by 2020, according to estimates put forward by the firm Allied Market Research. What’s more, based on information gleaned from various studies, the ethanol sector is concentrated mainly in North America, whereas biodiesel is produced mainly in Europe.

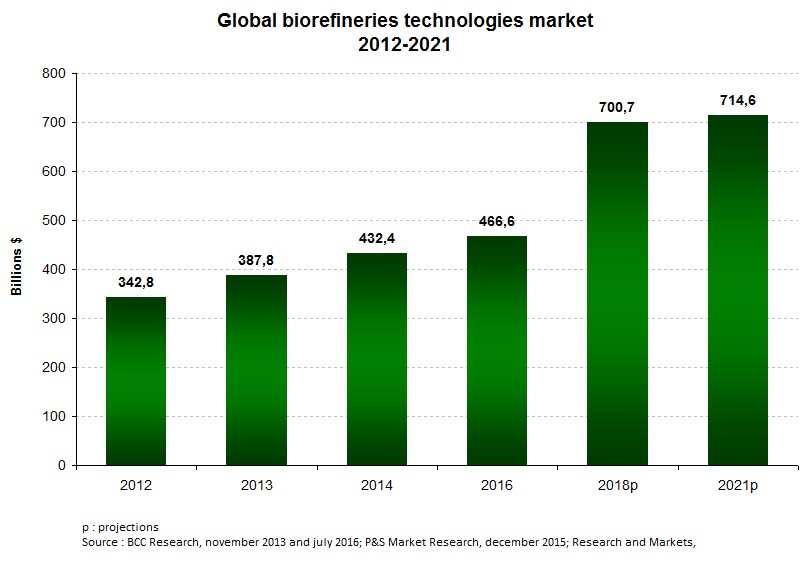

The biofuel market has grown on par with the evolution of biorefining technologies. The latter market was pegged at close to $467 billion in 2016, compared to $343 billion in 2012, which is equivalent to an average annual growth rate of 8%. Between 2016 and 2021, this market is expected to record an average annual growth rate of 9%, to reach $715 billion by 2021.

Positive growth in the biofuel market is strongly tied to research and development efforts, and Montréal is no exception.

LEADING-EDGE TECHNOLOGIES DEVELOPED IN MONTRÉAL THE DRIVING FORCE BEHIND THE DEVELOPMENT OF BIOFUELS IN QUEBEC

The use of non-food raw materials to develop biofuels has continued to gain favour among Montréal-based researchers. Indeed, second- and third-generation biofuels account for an emerging sector in Montréal, as evidenced by the technologies presented below. Innovative projects associated with these technologies are also being launched across Montréal territory.

From phytoremediation to bioethanol

Researchers at the Institut de recherche en biologie végétale (IRBV) are developing new technologies using plants. Among these are phytotechnologies that use living plants to solve environmental problems. Phytoremediation – the use of plants to decontaminate soils – is a prime example. Various plant species (i.e., fast-growing willow, poplar, fescue, flax, etc.) are evaluated for their decontamination and lignocellulosic biomass production potential.

The biomass stemming from this decontamination is then converted into bioethanol and other by-products, including phenolic compounds that can be used to manufacture industrial additives. The lignin thus extracted, for its part, can lead to the manufacture of adhesives for the aerospace sector. Processing the biomass obtained from soil decontamination is done through the use of various chemical reactions to separate lignin and cellulose. The extracted cellulose is then converted into sugar in two stages: enzyme digestion to liberate the sugars, and sugar fermentation in bioreactors to obtain bioethanol.

IRBV researchers have developed methods of measuring the potential of various plant species for convertion into biofuels. In fact, the diversity of plant composition influences the final performance of biofuels, notably when it comes to energy density. Comparisons drawn by these researchers revealed enormous variations between the plants. More specifically, they discovered that willows are economically viable for extracting bioproducts, including biofuels. According to Frédéric Pitre, head of the biofuel research division, the development of this renewable energy is an excellent means of generating revenue during the phytoremediation stage, which often spans an extended period.

Biobutanol made from forest residues

Researchers at the Centre d’études des procédés chimiques du Québec (CÉPROCQ), affiliated with Collège de Maisonneuve, are in the process of developing bio-industrial technologies with high added value thanks to the extraction, conversion and transformation of bioactive molecules. The technology they are developing is aimed at designing biofuels using forest products (i.e., bark, downgraded wood, forest wood waste, etc.). This lignocellulosic biomass is first pretreated to remove the lignin and keep only the sources of sugars, that’s to say the cellulose and hemicellulose. These sugars are then fermented and purefied to obtain ethanol or butanol. CÉPROCQ researchers are focusing their activities on the production of biobutanol. This bio-sourced product consumes less energy and is liquid and stable. It is easy to transport, therefore, and does not require mixing with petroleum products. The biobutanol developed at the CÉPROCQ is used as a platform molecule, meaning that it replaces the petrochemical butanol currently used by the chemical industry. Another relevant application for this biobutanol lies in the development of a second-generation biofuel. The lignin extracted is of high quality, that’s to say it is pure and low in molecular weight. It can be converted into other bioproducts, including natural adhesives and biomaterials used in transportation, health, and even in the aerospace sector.

One of the main problems with biorefining is the cost of pretreatment for purposes of extracting sugars. This cost accounts for 20 to 30% of total costs. In order to resolve this problem, CÉPROCQ researchers are developing a new technology based on supercritical fluids, i.e., “greener” solvents. At a low cost, these solvents will then be used to separate the sugars and lignin during the pretreatment phase.

An integrated biorefinery in Montréal East

The results of this promising research are on display at an integrated and energy self-sufficient biorefinery. The CÉPROCQ intends to complete this project in Montréal East in an effort to facilitate the city’s transition to green chemistry. The inputs used in this biorefinery will consist of biomass from lignocellulosic residues. This innovative biorefinery will:

- Treat up to two tonnes of materials per day;

- Produce a series of biosourced platform molecules, such as pure lignin, n-Butanol and lactic acid.

The success of this demonstration project could pave the way for the production of these molecules on a larger scale, with the goal of promoting the development of integrated technological solutions. The CÉPROCQ hopes to create this integrated biorefinery in partnership with chemical and petrochemical industries, with support from Montréal’s leading socioeconomic actors.

Capture of CO2 and conversion into biofuel

Professor Louis Fradette of Polytechnique Montréal does not view CO2 as waste, but rather as a resource that can be reused to curb greenhouse gas emissions. He has developed a “green” process for capturing CO2 using an enzyme called “carbonic anhydrase.” The development of this enzyme was inspired by its function inside the human body, where carbonic anhydrase eliminates excess CO2 from the blood. Adapted to an industrial context, the enzyme, when combined with a liquid, makes it possible to remove CO2 stemming from petroleum refining activities, cement factories and coal-fired electric power plants.

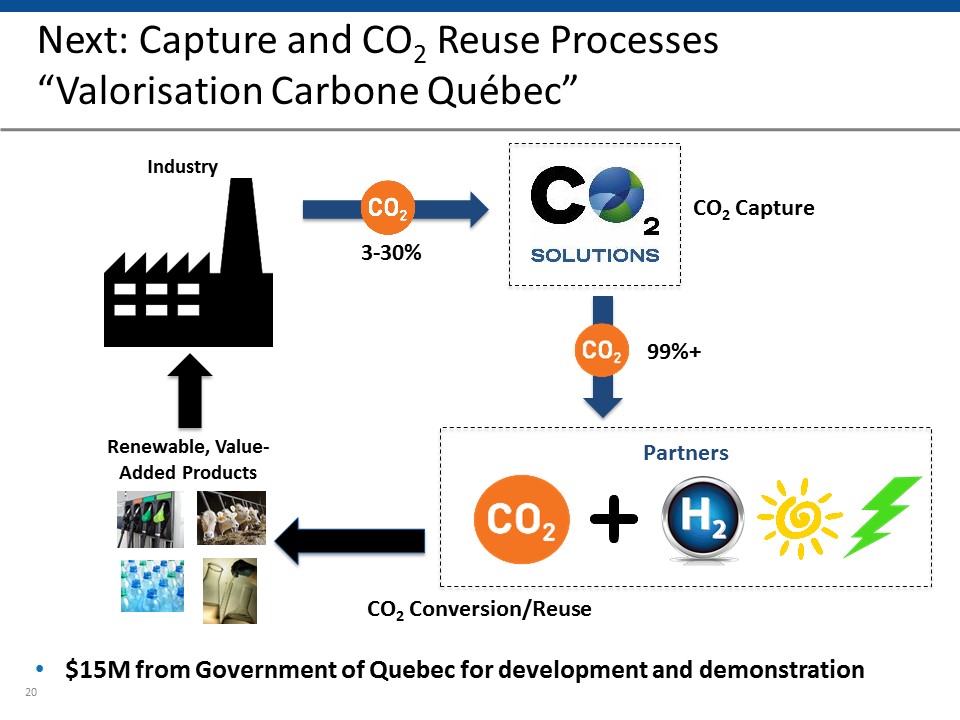

Valorisation carbone Québec, an innovative project for Montréal East

In connection with this enzyme technology, Professor Louis Fradette has teamed up with Quebec-based CO2 Solutions and other public- and private-sector organizations to launch an innovative project called Valorisation carbone Québec. Based on a revolutionary concept, this project is aimed at developing and implementing concrete solutions combining the capture of CO2 from major industries and its subsequent conversion into biofuel and other bioproducts (molecules such as acids, methanol, and ethylene glycols) using hydroelectricity. According to the researcher, the biofuel thus obtained would be carbon-neutral. What’s more, the same process used to convert captured CO2 could be carried out by biological means using bioreactors rather than electricity. This project – which has received support from the Government du Québec to the tune of $15 million – will be the subject of an on-site demonstration in Montréal East. Once the project has been completed, the most promising means of CO2 conversion will be retained and deployed on a large scale.

CO2 Solutions is a Quebec-based company specialized in carbon capture using enzymes. The company has developed a high-performance carbonic anhydrase enzyme named 1T1. The 1T1 enzyme has demonstrated catalytic performance that considerably surpasses that of the best enzymes currently available as well as those used to date by the company. Based on the developments observed thus far, this enzyme process has presented several significant advantages. The costs associated with the capture, sequestration and reuse of carbon using this enzyme are far lower than the costs associated with conventional processes, which require significant amounts of energy. In addition, the ground-breaking technology developed by CO2 Solutions is perfectly adapted to carbon capture from any source of combustion gas containing CO2.

A biofuel based on non-edible residues

Professors Gregory S. Patience and Daria C. Boffito, both members of Polytechnique Montréal’s Research Centre in Process Engineering – Biorefinery (CRIP), have developed a new biofuel manufacturing process that uses low-quality, low-cost non-edible residues. A solution containing used vegetable oil, a biomass derivative, animal fat and alcohol is injected into a catalytic reactor at high temperature in order to break the oil molecule. The result is a biofuel that offers cold-flow properties superior to those of conventional biofuel, which freezes at a temperature of close to 0 °C. This explains why conventional biofuel is used in low concentrations in winter and mixed with a large quantity of petrodiesel. The biofuel developed by these researchers remains liquid at temperatures lower than 0°C. It requires fewer petroleum-derived products, therefore, compared to the products currently available on the market. Successfully tested in the laboratory, the technology is available for transfer. A partnership with industry would thus make it possible to support its scale-up.

A high energy-density biofuel produced from sugars

As part of another project under development, Professor Gregory S. Patience and his team are producing a new biofuel using sugars derived from cellulosic biomass. The first stage consists of extracting cellulose from wood residues and then converting it into fructose or glucose by means of a technique called hydrolysis. The fructose or glucose thus obtained is then converted to produce dimethylfurane, an insoluble liquid in water. This new biofuel presents several major advantages compared to ethanol. Contrary to the latter, its energy density is 40% higher, while its boiling point is 20°C higher. This technology requires complementary studies in order to determine its industrialization capacity as well as its overall impact on the environment.

Converting gas from landfill sites into biofuels

On the strength of his expertise, Professor Patience has been called upon to serve as director of a joint project involving ME Resource Corp. (Vancouver) and Polytechnique Montréal. Launched in 2014, this project is aimed at recovering and converting methane from landfill sites into biodiesel or biogas. Methane is among the largest sources of greenhouse gases, second only to carbon dioxide. Various industrial activities release methane into the atmosphere, including petroleum production, waste water treatment and the decomposition of organic matter in landfill sites containing municipal solid waste.

Professor Patience and his team are developing methane-based biofuels. In a subsequent phase, they will assess and identify the landfill sites best suited to carrying out studies demonstrating the processes developed. This stage will result in the production of biofuels on a large scale, at a competitive price. For now, however, the researcher and his team are designing and optimizing processes on the laboratory scale. Professor Patience believes that the conversion of methane into biofuel represents an opportunity for Montréal.

Biodiesel made from sugars and microalgae

Professor Mario Jolicoeur, holder of the Canada Research Chair in Applied Metabolic Engineering, affiliated with Polytechnique Montréal, is undertaking research aimed at developing bioproducts and bioprocesses, notably through the conversion of residual waste. His current areas of interest include the development of second- and third-generation biofuels.

A microbial fermentation process used to produce biofuels from sugars

Professor Mario Jolicoeur and his team are developing a fermentation technology, that’s to say without oxygen, in order to produce solvents from organic matter. Two stages are used to convert second-generation biomass into biofuel :

- In the first stage, research makes it possible, through bioprocessing, to convert organic plant matter into fermentable carbohydrates (sugars);

- In the second stage, the microbial fermentation of these carbohydrates makes it possible to accurately extract butanol, a major ingredient in the manufacture of biodiesels.

According to the researcher, butanol can be used without adding petroleum products. Furthermore, says the researcher, this technology has the particularity of generating by-products with high added value, including a nutritional vitamin and chemical industry molecules. This research is being conducted in collaboration with Dr. Hassan Chadjaa of the Centre national en électrochimie et en technologie environnementales (CNETE) at Collège Shawinigan.

New bioprocesses for the production of biodiesel using microalga

Another innovative technology currently being developed by Professor Jolicoeur and his team involves the use of microalga to produce lipids destined for the development of biodiesels. These lipids – which are already present in microalga, albeit in low amounts – can be produced in larger quantities using various processes. The research undertaken is aimed at using three separate processes to develop algal biomass rich in lipids for conversion into biofuel :

- The first mode of production involves the use of algae to convert carbon. More specifically, CO2 is captured to feed microalga, much in the same way as plants do. The captured CO2 is injected into illuminated bioreactors in which microalga are cultivated to obtain algal biomass. The latter feasts on lipids, therefore, which are products of interest for the manufacturing of biodiesels.

- Another means of producing lipids using microalga consists of nourishing them with organic matter rich in sugar.

- Finally, a third, mixed process is undertaken by pairing the two previous modes of production, that’s to say by injecting the captured CO2, at the same time as the organic matter rich in sugars, into illuminated bioreactors in which microalga is cultivated.

Ultimately, other than the development of high-value biofuels using algal biomass, this research makes it possible to identify bioprocesses that offer superior performance for the large-scale production of this renewable energy. This research is being conducted in collaboration with Université du Québec à Rimouski Professors Jean-Sébastien Deschênes and Réjean Tremblay.

Combustion and characterization of biofuels

Professor Jeff Bergthorson, director of the Alternative Fuels Laboratory at McGill University, is developing sceintific methods intended, in part, to characterize the combustion of biofuels. These methods make it possible to measure greenhouse gas and nitrogen oxide (NOx) emissions from a range of alternative fuels by comparing them with emissions from fossil fuels. The results obtained demonstrated that NOx emissions from alcohol-based biofuels (i.e., butanol, ethanol, etc.) were lower than emissions from petroleum-based fuels.

As part of a collaboration with Siemens Canada, Professor Bergthorson is also conducting research on the use of biogas and hydrogen in gas-powered turbines. His project is aimed at designing turbines capable of consuming various types of fuels, thus giving them greater flexibility when it comes to fuel supply. The research carried out at McGill consists mainly of characterizing the differences in terms of the combustion of biofuels as well as the potential impact these differences could have on turbines. The findings could eventually lead to applications in the aeronautical, automobile and industrial sectors.

As a member of the Trottier Institute for Sustainability in Engineering and Design (TISED) at McGill University and the BioFuelNet Canada network, Professor Bergthorson is also developing new alternative fuels made from metal powder. These fuels are produced using renewable energy. According to Bergthorson, freeing our society from its dependence on oil and increasing the quantity of clean fuels requires that we multiply their sources of production.

ENERKEM AND EVOLEUM, TWO AVANT-GARDE COMPANIES IN MONTRÉAL

Montréal is home to a flourishing clean technology sector. According to Écotech Québec, an industrial cluster for clean technologies, Quebec has more than 500 innovative companies in the clean tech sector; among them are Enerkem and Evoleum.

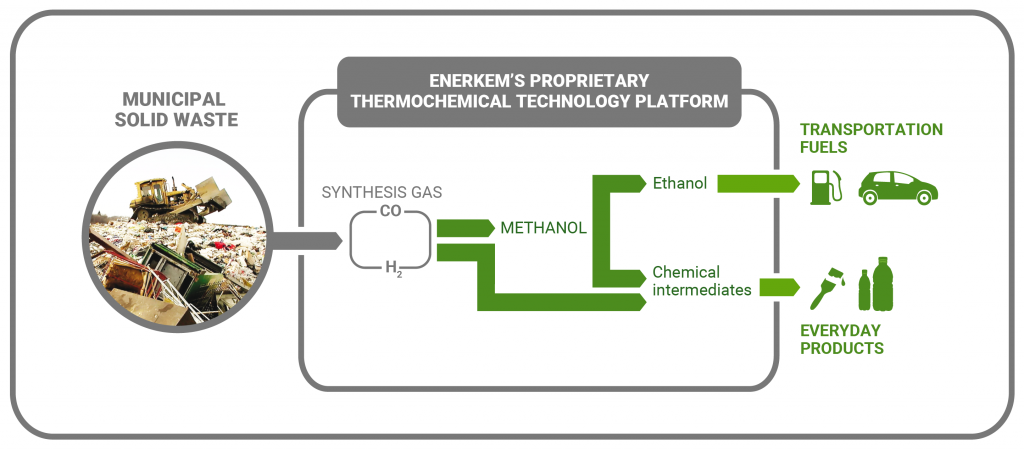

Enerkem | Cellulosic ethanol and biomethanol made from synthetic gas

Enerkem produces cellulosic ethanol and other renewable chemical products using non-recyclable, non-compostable or biomethanizable residual materials (i.e., wood, plastics, textiles, etc.) rather than traditional sources, such as corn and sugar cane. This waste comes from the institutional, commercial and industrial sectors.

Enerkem has patented a technology that consists of a green chemistry process (gasification) developed to produce a second-generation biofuel in two phases. In the first phase, carbon contained in residual materials is chemically recycled to obtain a pure synthetic gas called syngas. Syngas is essentially composed of carbon monoxide and hydrogen. In the second phase, catalysts are used to convert the pure gas into liquid biofuel. In under five minutes, the waste destined for landfill becomes clean fuel for transportation or renewable chemical products with added value. The Enerkem biofuel has the particularity of being non-toxic, water soluble and easily biodegradable. What’s more, it features a high octane index (fuel resistance), thus providing improved combustion. Another aspect of Enerkem’s technology is its low production cost compared to conventional methods, such as burial, which require greater investments. Developed using raw materials with little value, the technology also requires low operational energy intensity (i.e., temperature, pressure and electricity) and makes use of compact, leading-edge facilities. Moreover, it has been developed, tested and validated at the Enerkem pilot demonstration facility in the Eastern Townships as part of a rigorous technological development process, and implemented on a commercial scale in Edmonton, Alberta. The company’s next commercial plant is slated to open in Varennes, Quebec.

Other than ethanol, Enerkem’s process also makes it possible to produce biomethanol, an essential component in the manufacture of numerous chemical products, including solvents, bioplastics and textiles. Enerkem is forging partnerships with manufacturers of chemical products throughout the world, including in China, Canada and Quebec.

Evoleum | Biodiesel made from recycled fats

Evoleum has specialized in the production of biofuel using recycled fats, animal materials and cooking oils, including from restaurants. These oils come mainly from the Montréal region, but also from elsewhere in Quebec as well as Ontario and the United States. In biodiesel form, the biofuel – produced by virtue of a chemical reaction of the pre-treated oils in a bioreactor – is 95% biodegradable and non-toxic. As well, it requires no change in the equipment supplier or motor. Thanks to the use of recycled oils, Evoleum’s technology helps to curb the amount of waste that winds up in landfill sites, thus reducing organic soil and water contamination. The biodiesel produced by this Montréal-based company has applications in numerous sectors, including manufacturing and transportation.

In conclusion, it’s safe to say, in light of the technologies featured above, that Montréal’s low-carbon energy sector is growing by leaps and bounds, driven by the development of biofuels. Current research and development efforts point the way to the future growth of a new generation of biofuel technologies, with special attention on lignocellulosic and algal biomass, carbon capture, and the development of new enzymes.

This strong technological potential is being fulfilled amid a favourable governmental context. On the one hand, the Government of Quebec’s 2030 Energy Policy is aimed, in part, at promoting the development of bioenergy. On the other, the Ville de Montréal, with its Plan d’action SDÉ 2015-2017, is making green chemistry one of the promising mainstays of its economy. In particular, the city intends to develop an advanced biofuel sector. These two initiatives constitute opportunities for manufacturers of new-generation biofuels to stake out a position as economic drivers of the city’s economy, with the ultimate objective of reducing our dependence on fossil fuels.