SUMMARY

Residual materials: general considerations, principles and typologies

- Residual materials management

- Classification and typology

- Global economic benefits

- New economic model: the circular economy

Montréal-based innovations that are reclaiming our waste and promoting the circular economy

- Research Chair on Advanced Waste Recovery at Polytechnique Montréal

- Pyrocycle | Electronic waste reclamation

- RMTech | Electromagnetic irradiation used to reclaim waste from the pulp and paper industry

- Polystyvert | Innovative machine for recycling polystyrene

- Ecolomondo | TDP for recycling hydrocarbon waste

- Pyrowave | CMD for recycling plastic

The management of residual materials constitutes a crucial issue for societies, both in terms of the economy and the environment. Burial has been the most widely used technique to date, albeit one that presents considerable drawbacks. That’s because landfill waste, once buried, produces a non-negligible amount of carbon, thereby contributing to GHG emissions and water pollution. Sound management of residual materials is required to build a green and sustainable economy, therefore, and thus promote societal development and environmental protection, while preventing the shortage of resources.

The Government of Québec has made a strong commitment in this regard, by establishing policies, laws and actions plans geared to the effective management of residual materials. The 2011 Québec Residual Materials Management Policy and its 2011-2015 Action plan represent the most concrete examples. Aimed chiefly at eliminating only ultimate waste, this policy promotes conduct that is more respectful of the environment, together with best consumption and residual materials management practices.

In Montréal, residual materials management comes under the jurisdiction of the municipal administration. With the goal of reducing the volume of residual materials destined for landfills, the agglomeration of Montréal adopted the Plan directeur de gestion des matières résiduelles (Master plan for the management of residual materials – in French), which is aligned with the objectives and orientations of the Québec government.

The Plan métropolitain de gestion des matières résiduelles 2015-2020 (2015-2020 Metropolitan residual materials plan – in French), which came into force on January 28, 2017, constitutes another example of the commitment and the social and political will to ensure a “zero-landfill” future.

Meeting the objectives set by various levels of government requires that citizens do their part, notably by sorting residual materials at source, but it also calls for technology developers and researchers to get involved by developing innovations that address issues related to the sorting, conversion and reclamation of residual materials.

Driven by its strong innovation potential, Montréal is known and recognized for the expertise of its industrial entrepreneurs and researchers, who are developing leading-edge processes that not only divert residual materials from landfills, but also put them to good use.

Part 1 of this article concretely summarizes the concept of residual materials and the connected principles of management, together with the classifications and typologies currently used. It also presents a portrait of the economic benefits and potential inherent in their management. Part 2 features a non-exhaustive list of Montréal-based initiatives and innovations used in sorting, recycling and reclaiming certain residual materials.

Residual materials: general considerations, principles and typologies

A residual material is defined as any material or object that is discarded by households, industries, businesses and establishments, and subsequently reclaimed or eliminated.

The expression “residual material” signifies that our rubbish is no longer considered waste, but rather a resource to exploit and reclaim, with the potential to become secondary material that can be integrated into other manufacturing and production processes. Note that ultimate waste – that’s to say waste that cannot be reclaimed – accounts for only a small portion of our rubbish.

Residual materials management

Residual materials management is guided by principles that differ from one country or province to the next. In Québec, it is based on the principle whereby precedence is given to management methods with the lowest impact on the environment. Described under the acronym “4R-D,” it includes the steps to prioritize in order to ensure the effective management of residual materials. Thus, reduction at source, re-use, recycling, reclamation and disposal must be favoured, in that order.

- Reduction consists of curbing the amount of waste generated by the manufacturing, distribution and use of a product. Eliminating certain useless packages and changing our consumption habits are good ways to minimize the use of resources.

- Re-use concerns the repeated use of a product or package without changing its appearance or properties. The re-use of returnable beer bottles is one of the more tangible examples.

- Recycling involves a series of operations whereby a residual material is reintroduced into a production cycle, culminating in the creation of a product of the same nature (e.g., an aluminium can melted in order to manufacture lids for use in cans).

- Reclamation lends renewed value to residual materials through a chemical transformation that completely alters the nature of the product. There is a distinction between energy reclamation, whereby useful energy is produced by means of thermal treatment processes (such as waste incineration), and material reclamation, which refers to the replacement of a virgin raw material with a residual material used to produce a different product.

- Disposal is a final recourse. It denotes any operation aimed at disposing of waste without efforts to apply the 4 Rs. Disposal may refer to materials that are incinerated without reclaiming the energy they contain, or the ultimate disposal thereof in a landfill site.

Based on this hierarchy of management modes, reduction at source represents the best method. Otherwise, re-use is the most cost-efficient method, since, like recycling and reclamation, it doesn’t require that the materials be modified physically.

Classification and typology

Other examples of residual materials produced by households, companies and industries include organic residue as well as metallic, textile and plastic waste. Household waste may include plastic packaging or organic materials. Industrial waste, for its part, is generated through economic activity (industrial and manufacturing sectors, the housing industry, public works, etc.).

In accordance with the regulations and policies in force in Québec, residual materials may be classified based on the following categories: contaminated soil, biomedical waste, pulp and paper waste, inorganic waste, mining waste, organic sludge, radioactive waste, scrap tires, waste snow, scrap vehicles, and solid waste since 2006. Management methods have been established for each of these categories, it’s important to note.

Residual materials can also be divided according to the typology specific to each. Here are a few examples:

- Scrap electric and electronic equipment,including cell phones, computers, televisions and other electronic devices that have reached the end of their operating lives. This type of waste often contains recyclable materials with high commercial value, such as copper, silver and palladium.

- Plastic waste is produced from plastic materials and is essentially associated with packaging, construction materials and motor vehicle components. Thanks to its characteristics (i.e., resistance, versatility, durability and lightness), plastic is used as a substitute for several materials, including paper, glass and metal. Plastic waste lends itself very well to re-use, recycling and reclamation.

- Paper and carton waste is generated by the pulp and paper industry. It consists of products made from cellulosic fiber, the raw material extracted from trees, and includes newspaper, fine paper, tissue paper, corrugated board and cardboard. The pulp and paper industry has invested more in environmental protection than any other sector in recent years. Waste from this industry is well suited to re-use, recycling and reclamation.

- Scrap tires are made mainly of synthetic rubber, a petroleum derivative, and natural rubber from trees. Depending on their condition, scrap tires are recovered for purposes of remoulding, recycling and reclamation.

Global economic benefits

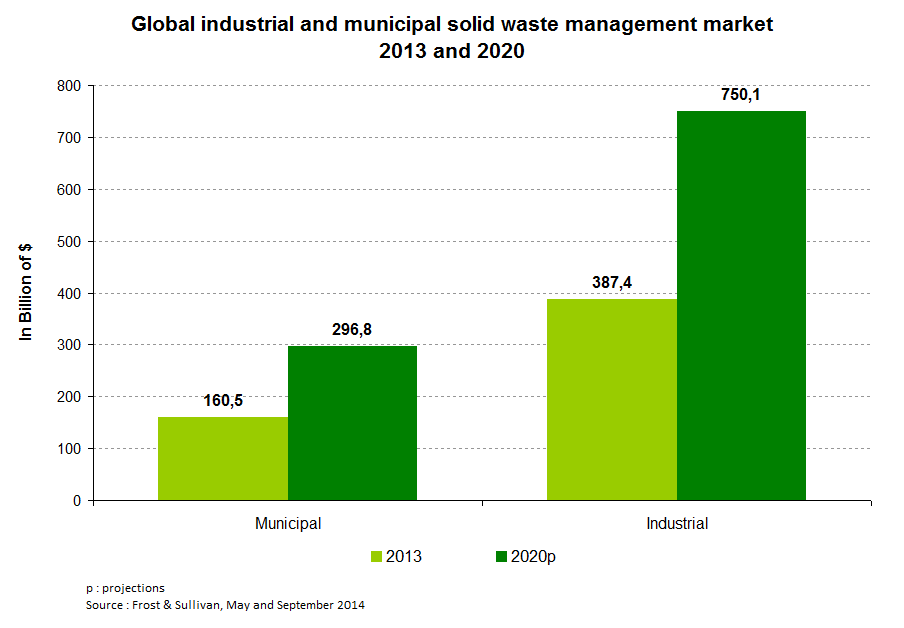

Global revenues from industrial solid waste management were estimated to be in the order of $387.4 billion in 2013. That figure is expected to rise by an average of 6.3% per year, to reach $750.1 billion by 2020. The global market for municipal solid waste, meanwhile, including waste from the commercial and residential sectors, was pegged at $160.5 billion in 2013. It is expected to reach about $297 billion by 2020, which is equivalent to an average annual increase of 9.2% over seven years.

The management of residual materials presents an opportunity for rapid growth for the electrical and electronic equipment, plastics, and pulp and paper industries.

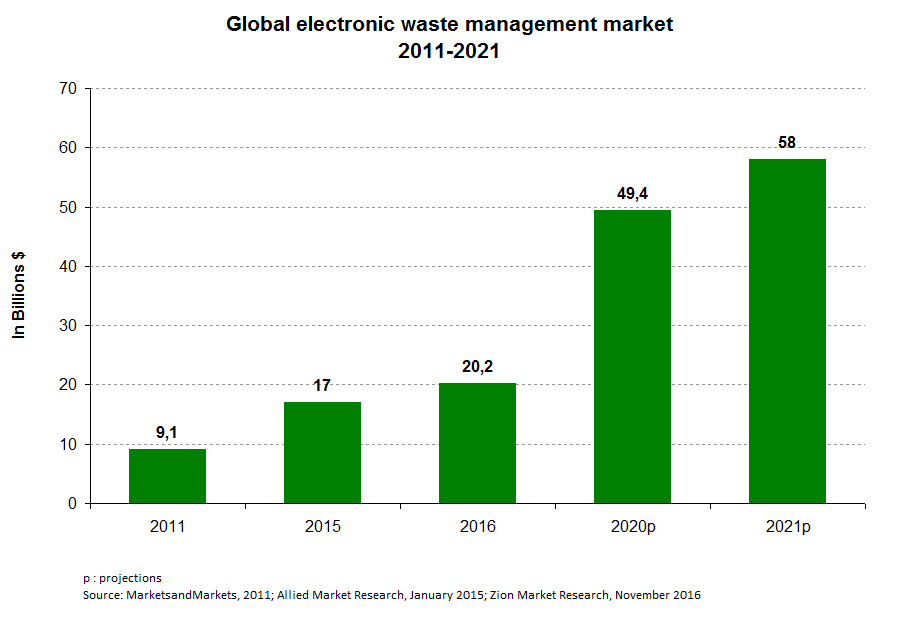

The global market for Waste Electrical and Electronic Equipment (WEEE) management rose from $9.1 billion in 2011 to $20.2 billion in 2016—a significant average yearly increase of 17.2% over four years. This market should reach $49.4 billion by 2020 and $58 billion by 2021, good for an average annual increase of 25% between 2016 and 2020. Between 2020 and 2021, this market should record an annual growth rate of 17.4%.

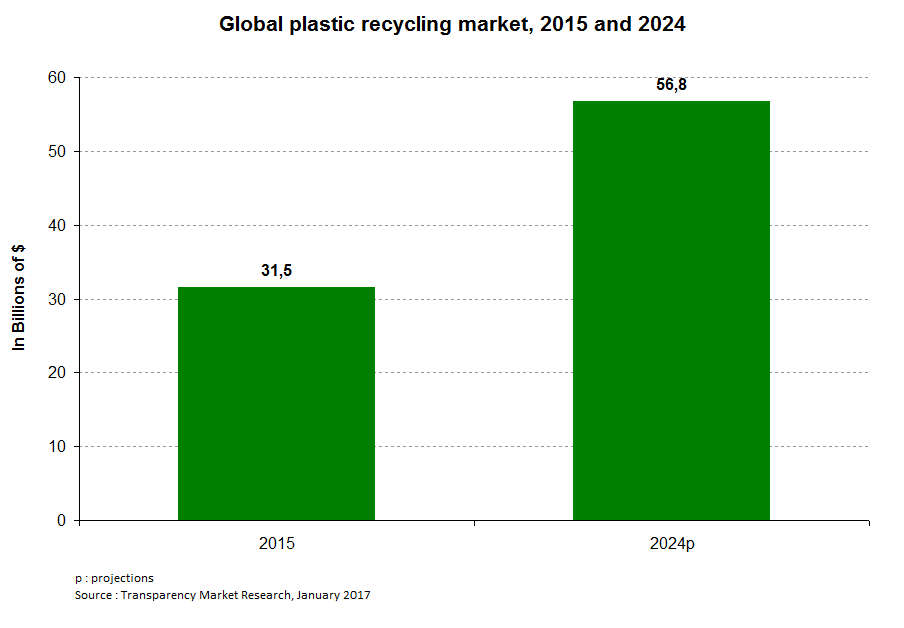

Plastics management, notably through recycling, accounted for a global market worth $31.5 billion in 2015. This market is expetced to increase by an average of 7% per year, to reach about $57 billion by 2024.

Waste paper management should generate a global market worth $43.35 billion by 2020. This market is expected to record average annual growth of 3%, to reach more than $50.42 billion by 2025.

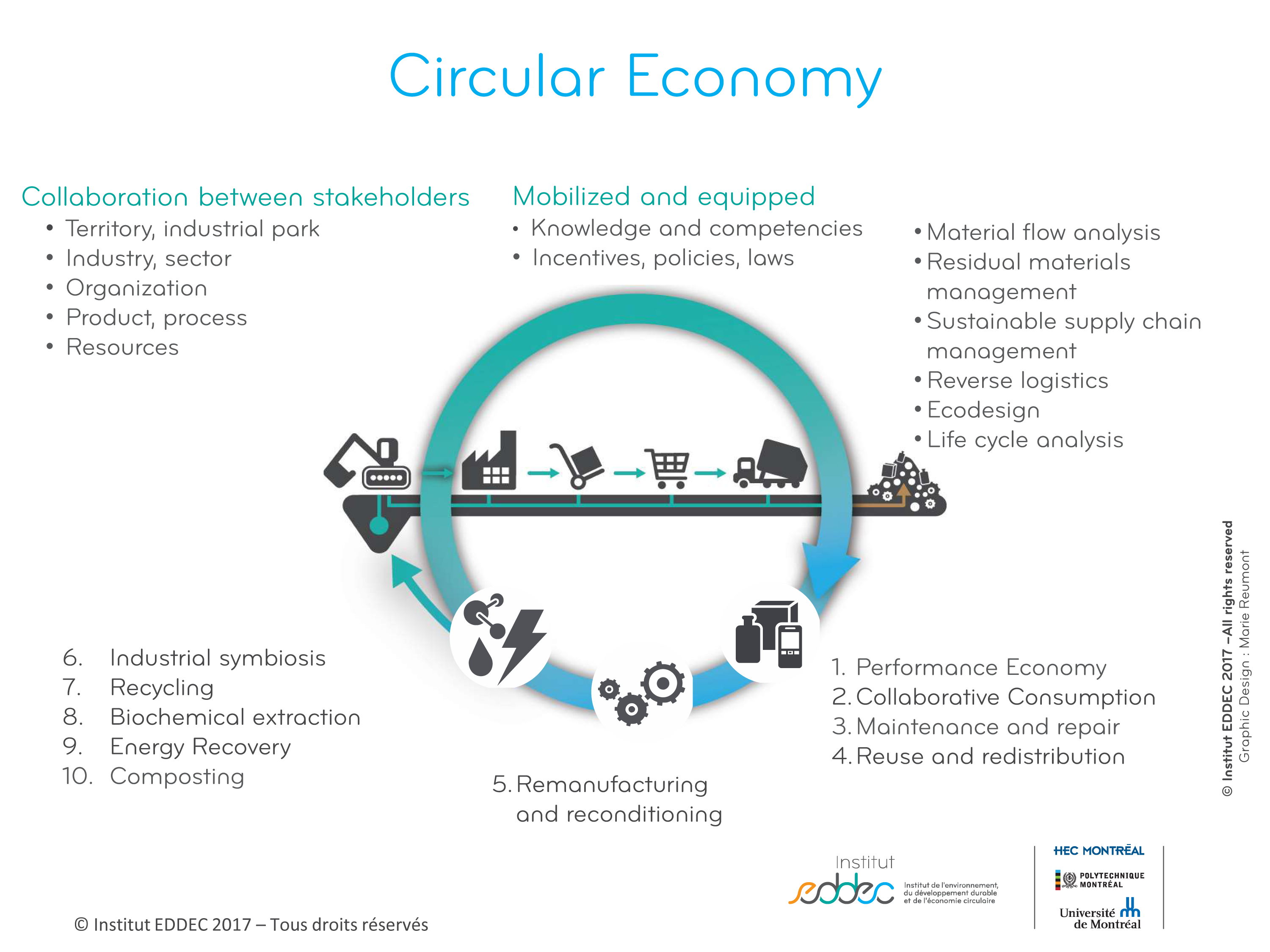

New economic model: the circular economy

The conventional economic model is based on a one-way linear system whereby raw materials are extracted, processed, consumed and discarded (see the figure below).

Source: Institut EDDEC 2015, instituteddec.org

The circular economy, by contrast, is an innovative model based on an approach whereby waste from one process become the resource for another. This new economy takes its inspiration from natural ecosystems in which the flow of matter and energy constantly circulates in a closed loop.

In concert with about 15 strategic actors supporting the deployment of the circular economy in Québec, the Institut de l’environnement, du développement durable et de l’économie circulaire (EDDEC) defines this economy as a “system of production, exchange and consumption aimed at optimizing the use of resources at all stages in the life cycle of a good or service, within a circular logic, while reducing the environmental footprint and contributing to the well-being of individuals and communities.” This economy, in other words, makes it possible to protect both our renewable and non-renewable resources as well as our ecosystems, combat volatility and the growing cost of raw materials, and curb pollution.

Researchers at the Institut EDDEC have created the diagram below, which illustrates perfectly the various components as well as the modes, conditions and tools related to the establishment of the circular economy.

It bears mentioning that the implementation of the circular economy requires the involvement of all actors, from consumers to industrial entrepreneurs and distributors.

Montréal-based innovations that are reclaiming our waste and promoting the circular economy

This section presents Montréal-based innovations in sorting, recycling and reclaiming specific types of residual materials that promote the circular economy. It’s important to specify that this article does not delve into the reclamation of biomass and plasma. Biomass reclamation was covered, in part, in the article published last month, whereas plasma reclamation will be discussed in a subsequent article.

Research Chair on Advanced Waste Recovery at Polytechnique Montréal

In November 2015, la Ville de Montréal and Polytechnique Montréal established the Research Chair on Advanced Waste Recovery, currently held jointly by Robert Legros and Réjean Samson, both professors in the Chemical Engineering Department at Polytechnique Montréal. Mr. Samson is also the director of CIRAIG. This initiative stems from a determination on the part of the municipal administration to resolve problems related to the reclamation of residual materials through the establishment of effective and innovative solutions.

The Chair’s chief mission is to meet the current and future needs of communities by optimizing their residual materials management and reclamation strategies, particularly those pertaining to household waste and organic matter. According to Mr. Legros, the leading objective consists of developing innovative processes and smart sorting methods.

The Chair’s research program revolves around three separate but complementary and closely connected themes: resources, reclamation, and impacts. This stems from the fact that optimizing the management of residual materials calls for the deployment of resource reclamation strategies that have a minimal impact on the environment and society.

After only one year of existence, more than 10 projects, each connected to one of the themes cited above, are under development as part of the Chair research program. The three projects presented below illustrate perfectly the integration dynamic behind the projects undertaken by the Chair holders.

Theme 1: Resources | Development of a predictive tool based on the analysis of material flow, for use in decision-making in residual materials management

The project led by Fabrice Tanguay-Rioux, a student in the Master of Applied Science program, is aimed at developing a predictive software tool capable of estimating the flow characteristics of residual materials in a municipality. Once configured with the parameters specific to the municipality under study, the tool will let the user evaluate the flow of materials and the composition thereof based on some 20 categories of materials and about 30 chemical elements. The user will thus be able to determine the flow of a specific material, such as paper, or a problematic chemical element, such as cadmium, in order to characterize the performance of the residual materials management system in place, the temporal trends specific to those materials, and their sensitivity to foreseeable changes in the system. The addition of a treatment centre and improved citizen participation in sorting at source are good examples.

Theme 2: Reclamation | Production of a refuse-derived fuel (RDF) using refuse produced by Montréal-based municipal sorting centres

Led by Camille Girard, a student in the Master of Applied Science program, this project is aimed at designing and sizing a mechanical treatment chain for purposes of converting a portion of the refuse flow from the municipal sorting centre into refuse-derived fuel. The fuel meets the specifications required for combined-combustion energy recovery within a high energy-consuming process. The methodology used to select and optimize the treatment chain – which conditions a flow with clean properties, for instance from a sorting centre refuse, in order to satisfy the constraints associated with the desired reclamation option – could then be extended and applied to other situations. The city’s future pre-treatment pilot centre could reclaim energy from certain portions of residual materials separated from household waste, for example.

Theme 3: Impacts | Optimization of residual material management systems based on the analysis of material flows and life cycles

The project led by Stéphanie Viau, a student in the Master of Applied Science program, is aimed at assessing the environmental impacts associated with Montréal’s residual materials management system, based on a combination of material flow and life cycle analysis methods. Several potential scenarios for reclaiming household waste (green bin) will be assessed and compared, and an optimization routine will be used to determine the optimal scenario.

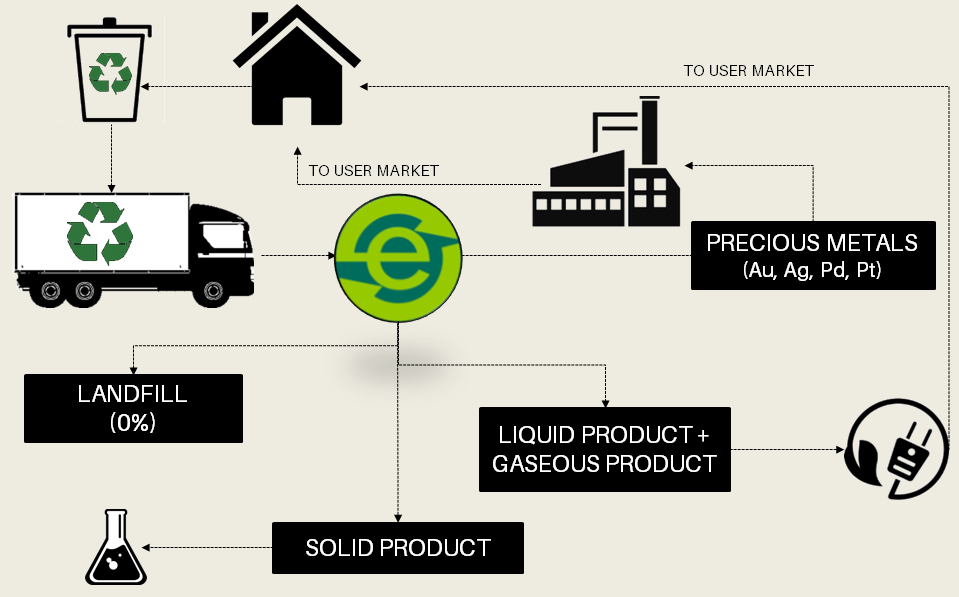

Pyrocycle | Electronic waste reclamation

In 2015, about 50 million tons of electronic waste were generated worldwide. A significant portion of this waste ended up in landfill sites, while the rest was shipped to developing countries. More importantly, this type of waste contains dangerous toxic materials that are harmful to the environment, such as brominated flame retardants (BFR).

Under the supervision of Professor Jamal Chaouki, Mohamed Khalil, a doctoral student at Polytechnique Montréal, has developed an innovative process capable of reclaiming all types of electronic waste, with no toxic gas emissions. Baptized “Pyrocycle,” this process uses microwave pyrolysis to break down molecules from the organic matter in electronic waste in order to develop products in the following forms: solid (carbon black), liquid (fossil fuel replacement solution) and gaseous (natural gas replacement solution). This innovation also makes it possible to extract precious metals, such as gold, silver, palladium and platinum, in a manner that is more effective than the standard methods used to date. Using a new chemical additive, Mr. Khalil is also able to capture in full the toxic gases emitted by brominated flame retardants (BFR).

Business model

Source : Image provided by Mr Mohamed Khalil

Based on a preliminary technical-economic analysis, the young graduate student estimates that the reclamation of 20,000 tons of electronic waste – the amount Quebecers produced in 2015 – could generate a gain of about $28 million.

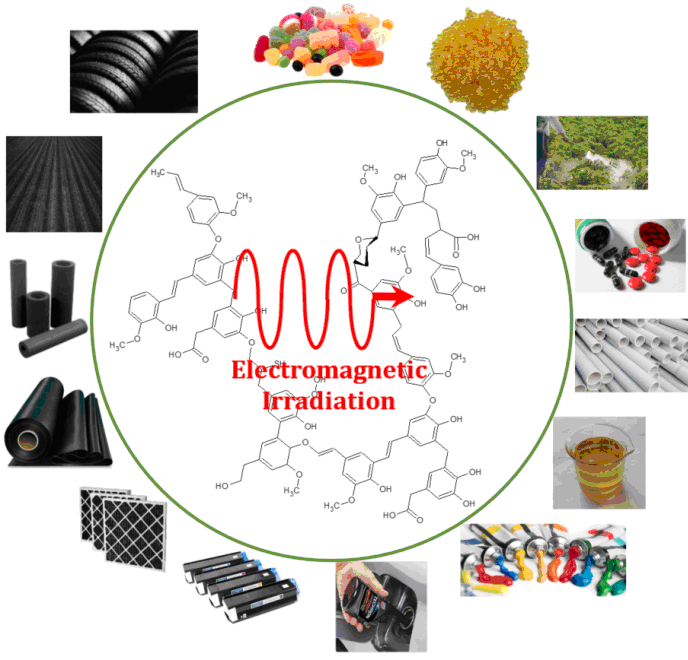

RMTech | Electromagnetic irradiation used to reclaim waste from the pulp and paper industry

In collaboration with Jamal Chaouki, professor in the Chemical Engineering Department and director of the Research Centre in Processs Engineering (CRIP) affiliated with Polytechnique Montréal, the company RMTech has developed a technology for reclaiming waste from the pulp and paper industry. The technology uses electromagnetic irradiation – that’s to say waves – to thermally decompose waste and produce carbon black and high-quality aromatic hydrocarbon. The green products thus obtained can replace a considerable number of chemical and petroleum-based products across several industrial sectors (see the image below).

Source: RMTech, rmtech.ca

- Hydrocarbons can be used as intermediates in the synthesis of pharmaceutical products, antioxidants, food additives, polymerization initiators, fuel additives, colorants, pesticides and raw materials used in the production of phenol-formaldehyde resins.

- Carbon black, for its part, is used in the production of electrostatic discharge compounds, high-performance coatings, tires and rubber, plastics, toners and printing ink, activated carbon, and soil additives.

The technology developed by RMTech significantly reduces the amount of thermal energy required to reclaim waste, thereby reducing operating costs and potential thermal risks.

According to RMTech CEO Sherif Farag, pulp and paper plants that integrate this leading-edge technology could generate additional revenues of close to CAN$8 million. Note that this estimate applies to plants with an average production capacity of about 100 tons per day.

Polystyvert | Innovative machine for recycling polystyrene

In Québec, more than 40,000 tons of polystyrene are buried each year. What’s more, the production of virgin polystyrene involves the suspension polymerization of styrene in water, which exerts a negative impact on the environment. This material is used to manufacture packaging for electronic products or furniture, food trays, as well as commercial and insulation products.

In order to protect the environment and at the same time reduce the amount of polystyrene in landfills and fossil fuel consumption, Montréal-based Polystyvert has developed an innovative technology for recycling all types of polystyrene: expanded, extruded, or injected. A three-step process is used to achieve this:

- Dissolution: The company has developed a machine, called a “concentrator,” which it installs on site where polystyrene waste is generated. Filled with essential oil, the concentrator converts the polystyrene into liquid in a few seconds. The company recovers the liquid periodically and replaces it with a new essential oil. This dissolution technique serves to reduce the volume of polystyrene at source, thereby curbing transportation costs and polluting emissions, as fewer trucks are required.

- Filtration: The liquid generated after the dissolution of polystyrene contains contaminants, such as labels, adhesive tape and plastic films, to name just a few. Using a grid, the contaminants are separated and the liquid is therefore filtered.

- Separation: The final step in the recycling process, separation constitutes the core of Polystyvert’s innovation. The company has developed an innovative process used to separate the essential oil from the polystyrene, thus making it possible to obtain a finished product of the highest quality. The polystyrene is resold and the essential oil reinjected into the concentrators installed on company sites, thereby closing the circle, so to speak, in the material recycling process.

“Concentrator”

On the strength of this innovation, Polystyvert has earned several awards and distinctions, including an Arista Award, an Estim Award and a Montréal Inc. Award.

Ecolomondo | TDP for recycling hydrocarbon waste

Hydrocarbons correspond to molecules found in products created from fossil fuels. At the end of its life, most hydrocarbon waste ends up in landfill sites, where it takes centuries to decompose and slowly releases toxins into our fragile ecosystem. What’s more, hydrocarbons are used as fuels, thereby creating carbon dioxide (CO2), the leading cause of global warming.

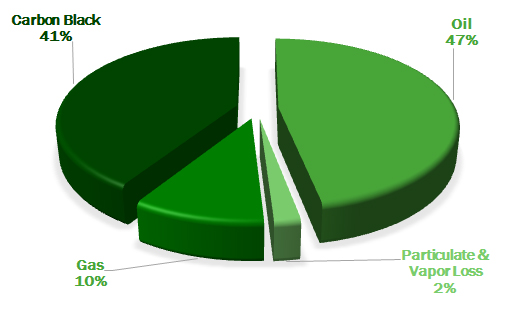

Montréal-based Ecolomondo, a worldwide leader in the treatment and reclamation of hydrocarbon waste, has developed a Thermal Decomposition Process (TDP), a green technology that recycles hydrocarbon waste into commodity products. This innovation draws on a pyrolytic platform that uses hydrocarbons from waste feedstock, including scrap tires, rubber, plastics, asphalt roofing shingles, automobile shredder residue (also known as “auto fluff”), and disposable diapers. Using heat and the absence of oxygen, the platform thermically alters the scrap tires, coverting them into quality, low-cost finished products with a reduced environmental footprint. These products include carbon black, oil and gas (see the diagram below).

TDP’s output (scrap tires)

Source: www.ecolomondo.com/technology-2

While the TDP can treat the most common hydrocarbons, thus far it has been commercialized solely for use on scrap tires.

According to Ecolomondo president and founder Eliot Sorella, this technology stands apart existing technologies owing to its simplicity, durability, reliability and profitability. “It was tested and validated by research centres at leading Canadian universities, including Polytechnique Montréal and the University of Western Ontario,” says Mr. Sorella.

Pyrowave | CMD for recycling plastic

The company Pyrowave has patented a new process to deal with the problem of plastic recycling. Dubbed Catalytic Microwave Depolymerization (CMD), this technology decomposes mixed plastics, converts them back into their initial constituents, or turns them into feedstock used to make plastics again.

The machine developed – a small modular unit – processes up to 100 kg of matter per cycle, with each cycle lasting 30 minutes. It is used directly by plastics producers and in recycling facilities. This proximity makes it possible to overcome a major obstacle: the high cost of transporting plastics. In the long run, this innovation could significantly improve plastic recycling rates.

Pyrowave adheres to a business model based on the circular economy. More specifically, the company collects liquid products generated by the machines, sells them to plastics manufacturers, and returns a portion of the sales to the machine operator.

Thanks to its business model and innovative technology, Pyrowave has been cited among the top-10 most innovative green technology companies at the 2017 Greentec Awards and the Katerva Awards.

As shown in this article, innovative technological solutions that optimize environmental performance represent one of several future growth sectors that are sure to heighten Montréal’s reputation for know-how on the world stage, while preserving its ecosystem and offering a strong and sustainable lever of economic development.

The innovations cited above, it’s important to mention, represent only a small portion of Montréal’s considerable innovation potential. The city has the expertise to serve as a model and an inspiration to other cities when it comes to managing residual materials.

In conclusion, collaboration from various actors involved in managing residual materials is paramount for determining the most effective means of diverting our waste away from landfill sites and ensuring a green and sustainable future.