There are concerted efforts worldwide to promote the electrification of transportation. Electric vehicles curb the use of hydrocarbons and ultimately decrease greenhouse gases (GHG).

According to the firm Bloomberg, electric vehicles could account for 35% of the world’s vehicles by 2040. This optimistic outlook is based on lower expected prices for lithium-ion batteries. In addition to being profitable in terms of the environment and the economy, the growth in the use of electric vehicles promotes the emergence of leading-edge technologies, not least energy storage devices and power optimization systems.

Energy storage makes it possible to preserve a given amount of energy in a device for subsequent use. Batteries and supercapacitors are the energy storage devices most widely used in electric vehicles. They are distinguished by their energy and power density.

- Batteries are known to have greater energy capacity than supercapacitors. They make it possible to continuously store energy for use over a longer period.

- Supercapacitors, meanwhile, only hold about 10% of the energy stored in batteries. They offer higher power density, however. In other words, while supercapacitors have lower energy storage capacity, they fill up in a shorter time span. They can also be used to recover energy on braking and restore it during acceleration.

Batteries and supercapacitors can be used in tandem to combine the benefits of both technologies.

Power electronics refers to a set of components intended to convert and deliver electrical energy in the form required by a vehicle. Without this technology, renewable energy could not supply the electrical grid. Power electronics technologies are used, most notably, to:

- Design compact lightweight electric motors;

- Develop charging systemsthat adapt electrical current to what the batteries can receive;

- Develop converters that transform continuous energy stored in batteries into alternating current, which a motor requires. They can also be used to convert renewable energy, for example from solar panels, into electrical current.

Thus, an electric vehicle’s autonomy depends not only on its energy storage capacity, but also on the effectiveness of its electronic commands.

This article presents the technological advances playing a key part in the burgeoning transportation electrification sector, with a special focus on fast-growing small and medium-sized enterprises (SME) in Montréal. Note that the term “electric vehicle” in this article refers to fully electric vehicles as well as rechargeable hybrid vehicles.

ELECTRIC VEHICLES, PROMISING MARKETS

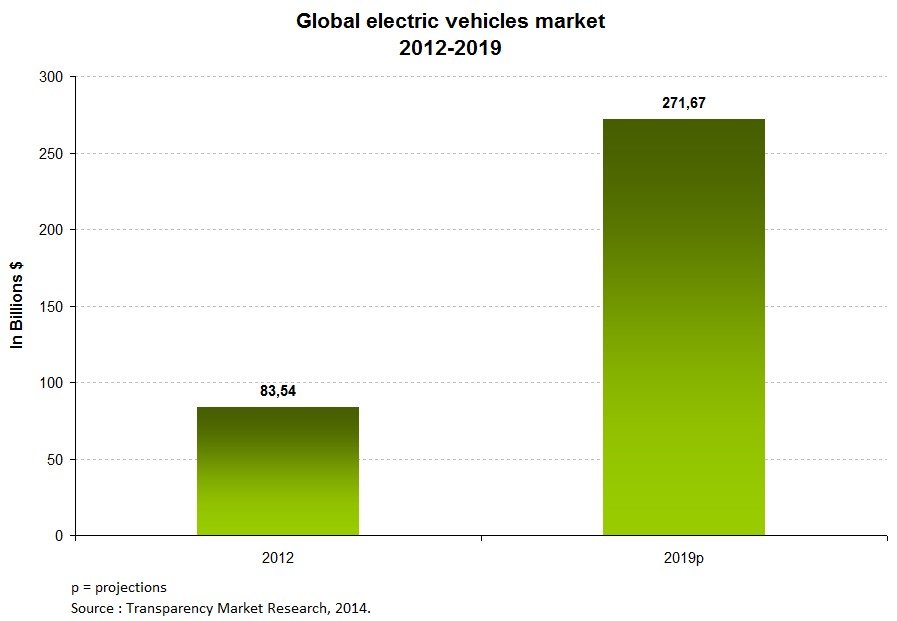

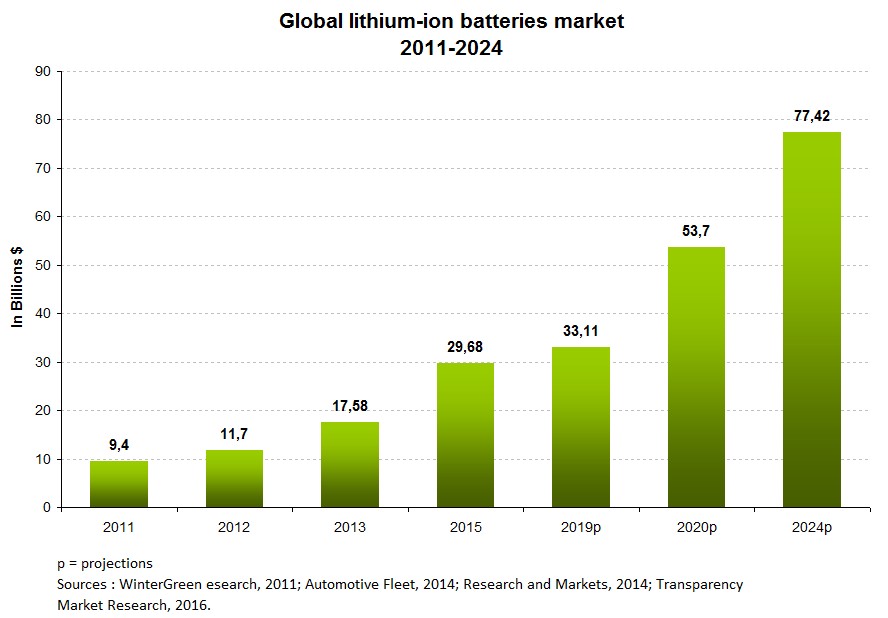

Prospects for progress in the global electric vehicle market are excellent. Estimated at close to $84 billion in 2012, this market should reach about $272 billion by 2019, which is equivalent to an average annual growth rate of 18.3% over seven years. What’s more, the growth in the electric vehicle market stimulates other markets, including the market for lithium-ion batteries. This type of battery is used chiefly in the electric vehicle field owing to its high energy density.

The global market for lithium-ion batteries was estimated to be in the order of $29.68 billion in 2015. It is expected to grow at an average annual rate of 13%, to reach $53.7 billion by 2020 and $77.42 billion by 2024, good for an average annual growth rate of 10% between 2020 and 2024.

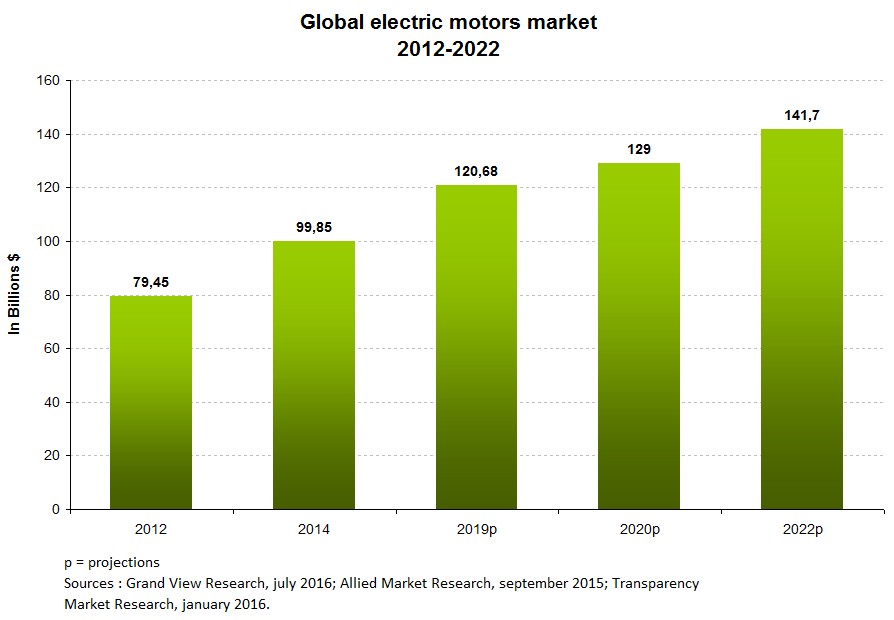

The global market for electric motors is also posting remarkable growth, on par with that of electric vehicles. Pegged at more than $79 billion in 2012, recent estimates put that figure at $129 billion by 2020 and about $142 billion by 2022, which represents an average annual growth rate of 6% over 10 years.

MONTRÉAL, A MAJOR HUB FOR LEADING-EDGE R&D IN TRANSPORTATION ELECTRIFICATION

Montréal is home to world-renowned researchers who have seized the opportunities offered by the electric vehicle market to further innovate. Their research holds the promise of a low carbon future rich in clean energy. It revolves largely around the development of charging infrastructures and new-generation energy storage devices, that’s to say devices that integrate renewable energy, along with devices that optimize power usage.

Renewable energy and smart charging algorithms

The team led by Professor Ambrish Chandra, a member of the École de technologie supérieure’s Power Electronics and Industrial Control Research Group (GRÉPCI), has developed various technologies for use in electric vehicles. These technologies are meant to meet ever-growing electrical consumption needs, and they rely on renewable energy.

Professor Chandra’s team is working to integrate emerging renewable energies, including solar energy, into the transportation and power distribution grids. More specifically, they have developed a system that optimizes the transfer of energy between photovoltaic panels on a building, an electric vehicle charging station, and the electrical power grid. This technology is intended for use in a Net Zero Energy Building, that’s to say a building that produces as much energy as it consumes over a period of one year, by using a variety of sources (i.e., solar, wind, etc.). If the energy generated by these sources is higher than household energy consumption, the difference can be used to recharge an electric car or can be sold to a power utility, such as Hydro-Québec. If the opposite is true, the distribution grid recharges the vehicle and meets household consumption needs. In the event of a power outage, however, the energy contained in the battery can be used to supply household electric devices.

This technology was subsequently adapted for use in remote regions with no power distribution grids. This is known as a so-called “off-grid” system. In this case, the technology provides for an optimal transfer of energy between solar panels on a building, a generator run on biogas, and the electrical charging system. Where solar energy is in short supply, for example at nighttime or under cloudy conditions, the generator makes up the difference and recharges the electric vehicles. Conversely, if there is a surplus of solar energy after the vehicle is charged, it can be used to power a water pump.

The advent of electric cars raises an issue in regards to the management of the electrical power grid. For this reason, Professor Chandra’s team, in collaboration with the Institut de recherche d’Hydro-Québec (IREQ), has developed a technology intended to integrate a fleet of electric vehicles into the power distribution grid. The technology makes it possible to measure the impact of charging and discharging and to use the energy of these vehicles to regulate the voltage and power profile in the electrical grid, in addition to minimizing the total cost of electricity and loss on the grid. During peak consumption periods, it is thus possible to use the electricity from other vehicles connected to the same transformer.

Finally, Professor Chandra’s research team has developed a technology that can predict whether or not an electric vehicle will reach its destination, based on the energy available in the battery and other internal and external parameters, such as traffic jams, weather conditions, and the distance to destination. This algorithm could be used to design a mobile application that tells drivers when they need to charge their cars and where the nearest charging station is.

Current GRÉPCI director Lyne Woodward is in the process of developing real-time optimization algorithms for use in renewable energy systems. These algorithms can be used to issue commands to power converters found, for example, in charging stations, in order to maximize the amount of energy transferred to storage systems at all times. The algorithms developed can be adapted to different types of renewable energy, including wind, solar or even biochemical (i.e., from microbial fuel cells). Lab tests have serve to validate the performance of these algorithms. The use of these algorithms in the transportation electrification field presents several advantages, from reducing the size or number of solar panels, to charging electric vehicles more rapidly.

Systemic design and control of electric vehicles power chain including cheaper position sensor

In collaboration with TM4 and AUTO21, Professors Pragasen Pillay and Luiz Lopes of Concordia University have teamed up with and Professor Ambrish Chandra of the ÉTS to design and develop a new motorization system for electric vehicles. The system features a high-powered converter (or inverter), a power supply control system, a position sensor, and an electric motor. The converter is used to transform continuous current from the battery into alternating current in order to supply the electric motor, while the electronic controller regulates the position and acceleration of the electric motor, thanks to signals sent by the driver and the sensor.

The research on the sensor was undertaken by Professor Ambrish Chandra and his team. They developed an algorithm that improves the performance of the position sensor used to control the permanent magnet synchronous machine (PMSM) in electric vehicles. This machine produces electric current based on the rotation speed of the rotor made of a magnetic material. It is responsible for producing the torque (rotation action for a given speed) and power required to propel the car, much as the internal combustion engine does on a gas-powered car. In a synchronous machine, rotation speed is determined by the frequency of the electric current circulating in the stator. Thanks to the technology developed, it is possible to detect the position of the rotor in this machine and control its optimal rotational force. The tests conducted on a real 80 kW machine produced good results. Compared to the previous solution, the sensor developed is ten times cheaper, with no deterioration in performance control. In tandem with this solution, Professor Chandra’s team has developed a technique for controlling this machine without a sensor. This technique can be activated if the position sensor is defective.

The findings of this collaborative research by Pillay, Lopes and Chandra have made it possible to develop a higher performance motorization system.

An electric motor that reduces energy loss

Professor Pillay, holder of the NSERC Hydro-Québec Industrial Research Chair on Energy Efficiency in Electrical Machines for Small Scale Renewable Energy Production Systems, is also developing the next generation of electric vehicle motors. His research, undertaken in collaboration with the IREQ, is aimed at developing a higher performance motor, that’s to say one that reduces energy loss when the vehicle is travelling at high speeds. Current electric motors don’t offer this kind of energy efficiency, says the researcher. Conversely, at low speeds, the energy used by these new electric motors is similar to that of conventional motors.

Wireless charging technology

Concordia University Professor Akshay Kumar Rathore, Chair of the Technical Committee on Transportation Electrification at the Institute of Electrical and Electronics Engineers (IEEE), a prestigious society of researchers from all over the world, is developing a wireless induction charging system for electric car batteries. Placed at ground level, this system would automatically transfer energy to the vehicle using the magnetic field, with no physical contact. To charge, the driver would simply park the vehicle directly above a terminal, without having to get out and plug in a cable. The technology developed by Professor Rathore would draw its energy from the electrical grid or solar panels. It would be adequate for shared infrastructures such as public charging stations or workplaces. Wired charging, for its part, would be better suited to residential settings, which require longer charging times. On top of integrating seamlessly into the environment and offering a dynamic aspect, wireless charging would hold advantages for persons with a mobility impairment, says the researcher, in addition to offering advantages during extreme weather conditions, including in winter. For the time being, however, it is 4 to 5 % less efficient than cable charging, which offers rapid charging.

Electric vehicles drivetrains with more energy-independent

In collaboration with TM4, Linamar (Guelph, Toronto) and Infolytica, researchers at McGill University’s Centre for Intelligent Machines (CIM) are in the process of developing a new drivetrain for electric vehicles. The new single-unit drivetrain would be composed of an electric motor coupled with a more compact and lightweight multi-speed transmission. Contrary to those used in conventional vehicles, the transmissions currently used in electric vehicles only have one speed. This integrated system is innovative in that it maximizes energy efficiency while reducing the weight, volume and cost of electric car motors. This more energy-efficient drivetrain would also be compatible with several types of transportation (i.e., cars, buses, trains, etc.). These research findings are sure to give rise to innovative projects. Indeed, CIM researchers expect to gradually electrify the McGill University bus fleet, with the first bus slated for testing in 2017. The flagship bus will serve the Macdonald campus in Sainte-Anne-de-Bellevue as well as the downtown campus.

Moreover, CIM researchers have used software applications designed by Montréal-based Infolytica to automatically optimize the design of this new generation of electric motors. The applications can be used to simulate electromagnetic fields and design electric motors, a highly important step that makes it possible to determine performance and better design the machines with the ultimate goal of reducing the cost of electric vehicles and their production time. Infolytica is known worldwide thanks to its collaborations with such major players as TM4, Hydro-Québec and Siemens.

CIM expertise in transportation electrification is also being harnessed as part of a joint project undertaken with TM4, Cummins (Indiana, United States) and Purolator. Purolator wishes to convert its gas-powered delivery trucks to electrical propulsion. Using TM4’s SUMO MD motor, researchers modelled and simulated the electrical powertrain design for the Purolator vehicle. The first electric truck will be tested in the streets of downtown Montréal in the spring of 2017, with the long-term goal of electrifying the company’s entire fleet of trucks.

New materials optimize lithium‑ion battery capacity by 10%

As part of his research activities at the Laboratory of New Materials for Energy and Electrochemistry Systems (LaNoMat) affiliated with Polytechnique Montréal, Professor Oumarou Savadogo is developing new cathode materials from lithium-iron phosphate (LiFePO4). These highly promising materials are used in lithium-ion batteries for electric vehicles. Lithium-iron phosphate is characterized by its excellent chemical and structural stability, non-toxicity, low cost, and abundance in nature. However, it is hampered by weak electrical conductivity and very limited ionic diffusion, and it operates solely at low current charge/discharge rates. In an attempt to resolve this problem, the researcher and his team have developed a dual approach using noble metal doping together with carbon-coated lithium-iron phosphate particles. More specifically, they used a platinum element to stabilize the crystal structure during the charge/discharge process and thus improve redox reaction speed, with a corresponding increase in the composite electrode surface. The platinum-doped electrode also presents small homogenous particles that could facilitate the lithium ion Li+ diffusion rate.

Professor Savadogo’s research team has shown that a gain of more than 10% in battery capacity is made possible by using the right carbon content and the proper method of preparing the electrode. These research findings have also demonstrated that doping this material, for example with less than 2%, by weight, of platinum, delivered a Li‑ion battery capacity of 140 mAh/g, whereas the electrode battery only delivered a capacity of 105 mAh/g. In addition to the remarkable increase in its capacity, battery life increased by 20% compared to the electrode battery not doped with platinum. Long-term durability tests under various charge/discharge conditions are underway with the objective of evaluating the conditions of use of these batteries in cars and buses.

Lithium-ion batteries for rapid charging and discharging of renewable energies

In collaboration with the company Phostech Lithium (now Johnson Matthey battery Materials Ltd), Professor Steen B. Schougaard, director of the Research Centre on Nanomaterials and Energy (NanoQAM), has developed composite materials for use in high-performance lithium-ion batteries. Thanks to the addition of a conductive polymer that coats the nanoparticles contained in these lithium-ion batteries, Professor Schougaard obtained a material that allows these batteries to store and draw renewable energy more rapidly, including from wind and solar and from hydraulic power. In other words, the energy stored in these batteries is not only green, but the battery charge time is also minimized. This leading-edge research holds enormous advantages for Canada, and particularly for Quebec. The technology developed benefits the emerging market for hybrid and electric vehicles and makes it possible to use hydroelectric resources – which are in abundant supply in Quebec – to reduce our environmental footprint and solve the problem posed by energy intermittency.

A supercapacitor with built-in power converter

Professors Frédéric Sirois and Georges-Émile April of Polytechnique Montréal’s Laboratory in Electrical Energy (LEE) have used supercapacitors to develop an energy storage tool that also features the functionality of a power converter. This device can be connected directly to an electrical grid, therefore, somewhat like a battery plugged into a regular electrical outlet. The device is equipped with switches controlled via a microcontroller capable of executing any type of energy conversion (AC-DC, DC-AC, AC-AC, etc.). This integrated modular system was developed with a view to maximizing the energy stored by the supercapacitors at all times and solving the problem of electromagnetic interference caused by conventional converters. What’s more, in the event that one of its components malfunctions, the system can continue to operate without a service interruption, which is not the case with a conventional supercapacitor- or battery-based storage system. The device could be loaded onto the vehicle or installed in charging stations, close to railway lines, etc. The design under development is optimized for transportation applications involving considerable energy consumption (e.g., trains, métro cars, buses and trucks). For example, it could serve as an energy reservoir for high-power charging stations for electric buses. The invention also makes it possible to facilitate the production of renewable energy (wind and solar), which is often irregular.

An activated carbon supercapacitor

Current research undertaken by Professor Daniel Bélanger at NanoQAM is aimed at developing electrochemical supercapacitors that are more inexpensive and stable, that’s to say they operate for as long as possible while optimizing performance. One of the main tasks of this research consists of significantly improving energy storage capacity in new electrochemical supercapacitors. The researcher uses several types of material, including electrodes such as activated carbon, as well as electrolytes. These electrodes, used in combination with other organic and inorganic materials, may make it possible to increase the amount of energy stored in these devices. The technology developed could be used in several means of transportation, including cars, buses, trucks, trams and planes. According to the researcher, these electrochemical supercapacitors can be used jointly with batteries, and the energy lost while braking a vehicle can be recovered for purposes of charging the batteries.

ÉTS smart electrical mini-grid: An innovative project for Montréal

INNOVATIVE SMEs ACTING AS ELECTRIC VEHICLE ACCELERATORS

The success and scope of transportation electrification also hinge on the know-how of innovative SMEs. Montréal is home to companies with strong potential in this field.

Renewz | Innovative solar carports for electric charging

In order to align itself with transportation electrification and renewable energy initiatives, Renewz is developing carports equipped with photovoltaic panels in order to generate, store and use energy. Dubbed iSun, these innovative solar carports make it possible to charge electric vehicles using the energy stored in a stationary battery or an electrical panel connected to a charging station. This is referred to as an « off-grid » charge, in the case of the battery, or an « on-grid » charge in the case of the electrical panel. With technology perfectly adapted to standards in each region, these modular solar carports can be customized and installed on commercial, educational, industrial and even government sites. The iSun platform was launched in Israel in conjunction with the mayor of Montréal’s trade mission to that country. Renewz is collaborating with solar technology and electric vehicle manufacturers, including the Innovative Vehicle Institute, the Giulio Barbieri development and production centre in Italy, and Inbar Solar Energy, a company based in Israel.

EcoTuned Automobile | An electric drive system that’s unique in the world

EcoTuned Automobile has developed the world’s first reusable electric drive system. This technology is designed to convert gas-powered light trucks into electric vehicles. By drawing on the electric motor’s million-kilometre lifespan and taking advantage of the similarity between light trucks, the system can be installed and easily reused in 85% of light trucks, with standard tools used in most automotive workshops in North America. This solution – the only one of its kind in the world – is spurring the rapid creation of electric vehicles, and it pairs economic profitability with innovation and sustainable development. Indeed, clients can benefit from considerable savings, including lower operating (80%) and maintenance costs (50%), while reducing greenhouse gas emissions (GHG). This patent-pending technology is slated to hit the market in 2017.

Effenco | A “Stop-Start Active” system driven by supercapacitors

Effenco is developing partial electrification solutions for heavy-duty trucks with the objective of eliminating fuel consumption associated with idling. More specifically, this Montréal-based company has patented a technology called “Stop-Start Active.” When a vehicle is stationary, this technology automatically interrupts the injection of fuel, thus stopping the motor, while allowing the other accessories (like the air conditioning and hydraulic equipment) to keep operating. This is made possible thanks to the use of a hybrid starter-generator and an electric “PTO” (power takeoff), both of which are powered by supercapacitors. The technology developed by Effenco has achieved several concrete results, not least a 30% reduction in fuel consumption, a 50% reduction in the number of hours during which the motor is running, and a positive return on investment. This innovative solution is used by clients throughout the world, including in Montréal (Derichebourg), Canada (Port of Vancouver) and the United States (New York City, Port of New York).

SG2B Electric | Planning and management of the electrical grid

Setting a course for the future, notably with the arrival en masse of electric vehicles, Montréal-based SG2B Electric has developed a planning software application for use in smart electrical grids. Its expertise in simulating these grids makes it possible, in particular, to determine the best possible location to install charging stations, be it on commercial, residential or industrial sites, or in government buildings. SG2B is able to validate the potential impact of a fleet of electric vehicles on the distribution grid and on electrical power generating facilities in order to better plan their management. The application makes it possible to design charging methods or energy storage technologies intended to solve power deficit problems, but also charging methods capable of tracking variable demand for solar and wind energy. This solution is thus aimed at increasing the capacity to integrate electric vehicles into power grids with a strong penetration of renewable energy.

Mogile Technologies | Localization of charging stations

Montréal-based Mogile Technologies is known for its ChargeHub Web and mobile platform. This technological platform meets several needs in the electric vehicle field. On the one hand, it allows electric car drivers in Canada and the United States to locate all the public charging stations in order to plan their itinerary, with the status of the charging station indicated in real time. This company offers its American clients the option of using the application to activate and pay for charging. What’s more, the platform features tools geared to car dealerships, allowing them to order residential charging stations for their clients and recommend electricians qualified to install them. This service is offered across Canada and the United States, and more than 125,000 users have subscribed to date.

The burgeoning electric vehicle sector in generating excitement worldwide, and various players, public and private, are jumping at the opportunity to curb GHGs. Attention is focused squarely on technological developments that further promote the deployment of these types of vehicles.

Montréal is particularly well positioned when it comes to innovations in this field. Technological advances achieved across its territory span several fields related to electric vehicles, from the development of high-performance batteries and supercapacitors, to the integration of renewable energies into the electrical grid. In addition to this fast-growing technological offer, Montréal continues to draw major international events, such as EVS29, which plays host to global industry leaders.

In conclusion, it’s important to remember that the transportation electrification sector is a priority for the Ville de Montréal. The city has adopted its Transportation Electrification Strategy for 2016-2020 aimed at deploying a network of electric charging station across Montréal.